News Category

Archive

Newly Posted

“Importance of the lapping process of scope rings” written by Satoshi Matsuo, Deputy editor-in-chief at Gun Professionals Magazine and Guns & Shooting Magazine (Japan)

Posted 07/26/2022

We sometimes receive inquiries if scope rings need to be lapped. As a manufacturer of precision optical instruments, it is suggestable that you lap the scope rings. This is because while a single product will stay within tolerances and not cause problems, multiple products stacked on top of each other can add up to manufacturing tolerances and, in rare cases, exceed tolerances. However excessive lapping will lead to counterproductive effects and there are several precautions to take during the process. In most cases such as March rings may not require lapping. The risk can overweigh the benefit of this process unless the rings are properly lapped by somebody proficient with right equipment. You need to make sure that the scope rail is not bent or lapping will be useless. If you are interested, it is highly recommended that you consult with your gun smith before performing. Below is a detailed informative article translated into English, written by Satoshi Matsuo, a notable Deputy editor-in-chief at Gun Professionals Magazine and Guns & Shooting Magazine in Japan. For your intellectual curiosity, it may be worthwhile to learn why lapping the scope rings is necessary and the recommended instruction to do so.

Why the Scope Ring Lapping Process is necessary & the Recommended Lapping Instructions

Written by Satoshi Matsuo

Deputy editor-in-chief at Gun Professionals Magazine and Guns & Shooting Magazine

(Part1) Why the scope ring lapping process is necessary

(1) Introduction

Unfortunately, the need for scope ring lapping alignment has not been properly recognized. When attaching a scope to a gun, commercially available rings are attached to the gun, and if the scope is placed and secured as is, it may scratch the scope body, or in the worst case, damage the scope itself. Nonetheless, most shooters are unaware of this possibility. In addition, when you remove the scope from the gun and also remove the scope ring, you may find a faint scratch on the tube part of the scope. You may think that it is natural that there are marks on the ring (mounting marks) because the scope was mounted on the gun. If the scope is mounted in the proper way, such marks will hardly ever appear on the scope. Scope ring lapping alignment is a necessary part of proper scope mounting. If this is done, the chances of damaging or scratching the scope are greatly reduced.

(2) Why is a lapping alignment needed?

A gun is an industrial product. Scope rings, scope bases, and scopes are industrial products. Industrial products have manufacturing tolerances. Manufacturing tolerances are the tolerances that allow for a certain degree of dimensional error in the manufacture of individual parts. This ensures that the quality of each product is consistent. If it is a single machine, no problem will occur as long as it is within the tolerances. However, when a scope is mounted, a mounting base is attached to the gun, a scope ring is attached to it, and the scope is fastened to it. Multiple industrial products made in pieces are stacked on top of each other to hold the scope in place. While a single product will stay within tolerances and not cause problems, multiple products stacked on top of each other can add up to manufacturing tolerances and, in rare cases, exceed tolerances. In extreme cases, the height of the front scope ring may be different from that of the rear scope ring. If the scope is placed there and tightened and secured, the scope body will be distorted. If the body of the scope, which is an optical instrument, is distorted, the optical axis will be out of alignment. This is what we mean by the possibility of damaging the scope. Tightening the scope will apply excessive force, which will also scratch the body. You may think that expensive rings and scope bases made by first-class manufacturers are made with high precision and that this will not happen. In reality, however, such problems do occur even with expensive products. The same is true for front and rear integrated rings and integrated bases. There is no guarantee that the receiver is perfectly dimensioned, even for the body of the gun to which the base is attached. Just as the ground is prepared for construction, it is necessary to make sure that the scope ring, which is the ground for the scope, is correctly attached to the front and back.

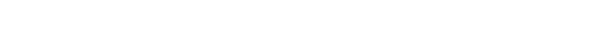

(3) Ring alignment tools

The ring alignment tool is used to check whether the front and rear rings are installed in the correct position. It is a metal bar with the same diameter as the scope and a pointed end. It is a precision-machined cylinder with a perfect conical shape at the bar and its tip.

Attach the scope base to the gun, and the lower half of the scope ring both front and rear. The upper half of the ring is then installed with the conical part of the ring alignment tool facing each other, and the ring screw is secured with the appropriate torque value*. If the conical tips of the alignment tool face each other and make precise contact, the front-back position of the ring is correct. In most cases, this will be the case. However, if this is not the case, some damage to the scope is inevitable if the alignment process is not performed.

*Please check the link below for the proper torque value. https://marchscopes.com/wp-content/uploads/2021/12/Torque-english-2021.12.9.pdf

(4) Even if alignment is good, machining is necessary

It is not necessarily true that alignment processing is unnecessary as long as the cone tips are in precise contact. In many cases, the scope rings have been surface treated in some way. If this is not done correctly and there is even a slight unevenness on the inside of the scope ring, it may scratch the scope. Even the slightest cutting mark on the edge of the ring can also scratch the scope. After all, the scope is held in place by the ring with great force. It is probably mainly due to these cutting marks that scope rings develop wear marks.

(5) Working procedure

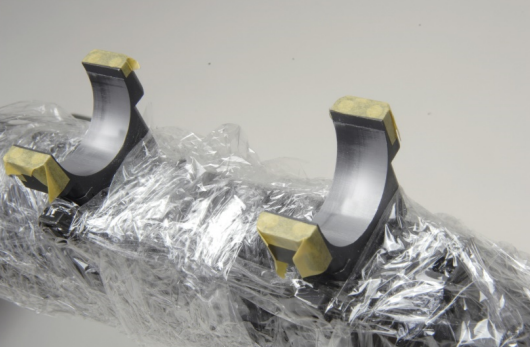

Fix the gun body to the gun vice and attach the scope base and the lower scope ring. It is recommended to use the proper torque value specified for each base and ring. When starting the lapping process, it is recommended to lap the gun body with plastic wrap and apply masking tape on small parts to prevent the lapping compound from splashing into the gun body or other parts of the ring.

In this procedure, only the lower part of the ring is lapped, while the upper part is lapped separately. Some instructional videos show lapping with the top of the ring attached, but we do not recommend this method for two reasons.

1. Excessive lapping of the top and bottom together will likely make the inner diameter of the ring itself larger than the scope tube, which will result in lax fixation of the scope.

2. Excessive load is placed on the screw that fixes the upper and lower scopes together, possibly damaging the screw.

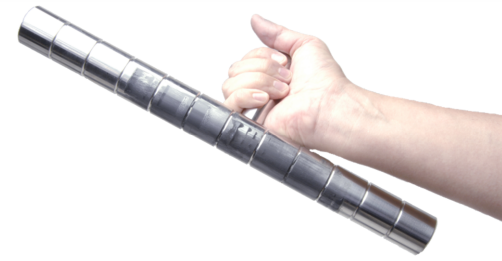

Apply an appropriate amount of lapping compound to the scope contact surface on the lower side of the ring. You can put the compound on your finger or other object and apply it just enough to cover the entire surface. Use a lapping bar to sharpen (lap) the ring by adding rotation as well as back and forth movement to align the front and rear rings. Excessive lapping is not necessary. If the inner diameter of the ring is larger than the outer diameter of the scope tube, the ring will not be able to fulfill its function as a ring. After lapping, wipe off the compound completely and remove the masking tape and plastic wrap.

The scope contact surface on the upper side of the ring should also be lapped. Lapping is done one ring at a time, holding the ring in your hand. After masking off the ring screw holes, etc., apply compound to the scope contact surface of the ring. The amount of compound should be less than half of that used for the lower side of the ring. This is because the purpose of lapping the upper ring is not to align it, but to eliminate uneven paint and cutting marks on the ring. The work can be done by holding the lapping bar in your hand and the ring in the opposite hand, and then making back-and-forth and rotational movements.

After completing the lapping process here as well, wipe off the compound and remove the masking tape. The compound should be completely removed after lapping, regardless of whether it is on the upper or lower side of the ring. If you do it halfway, you may damage the scope. In addition to simply wiping off the compound, it may be effective to carefully wipe it off with a cloth full of oil.

(6) About the compound to be used

Since this is basically metal polishing, abrasives should be used, ideally in the form of paste. Powdered abrasives are difficult to grind evenly and can easily contaminate the gun body, so they should be avoided. Wheeler which sells many firearms-related tools in the United States, has commercialized a lapping compound suitable for this task. LOCTITE CLOVER Compound is also suitable. Generally, a grid value of #220 to #240 is appropriate, and anything rougher (smaller number) or finer (larger number) than this should be avoided.

(7) Please note the following

As with the bore of a rifle, the inside of a scope ring should not be smooth and shiny. If the scope rings do not have a certain degree of roughness, the inertia caused by the recoil of shooting may cause the scope to slide and shift its position. Excessive lapping is therefore counterproductive. On the other hand, very inexpensive scope rings, for example, may fail without significant lapping.

It is strongly recommended to cover the body of the gun with plastic wrap and small parts with masking tape to prevent the compound from splattering and contaminating the firearm and other components.

(*All work related to firearms, including lapping, must be done at your own risk. We cannot be held responsible for any problems that may arise from this work.)

(Part2) Recommended Lapping Instructions for Scope Rings

(1) Use the lapping alignment tool this way.

If the conical tips are perfectly aligned, there is no need for alignment in principle. Even so, it is safer to have the ring deburred by lapping.

(2) Scope ring

In principle, alignment should only be done on the lower part of the ring.

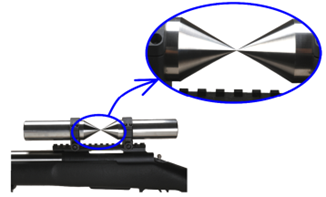

(3) Mounting scope base and rings

Attach the scope base and the lower side of the ring. Use a torque wrench to install the scope base and the lower ring at the proper value*. When working on the gun, make sure the gun is securely mounted on the gun vice.

*Please check the link below for the proper torque value. https://marchscopes.com/wp-content/uploads/2021/12/Torque-english-2021.12.9.pdf

(4) Cover the gun securely with plastic wrap to avoid contamination of the gun body with compound during the work. Masking tape should be applied to the smallest parts such as screw holes to avoid contamination of the gun body with compound during operation.

(5) Apply lapping compound to the inside of the mounting area at the bottom of the ring.

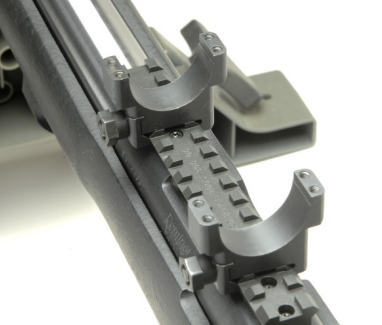

(6) Move the lapping bar moves back and forth and rotate it to align the front and rear rings.

(7) The lapping bar gets dirty like this. After the work is completed, wipe off the compound cleanly.

(8) The inside of the lower part of the ring will look like this after wiping off the compound. It is not necessary to make it smooth and shiny. The right amount of roughness must remain. Make sure to cleanly wipe off the compound. After this, apply a small amount of compound to the inside of the upper half of the ring and lightly lap the ring in your hand.

(9) Wipe off the compound carefully and install the scope with caution. Use a torque wrench to install the scope at the correct torque value.

*Please check the link below for the proper torque value.

https://marchscopes.com/wp-content/uploads/2021/12/Torque-english-2021.12.9.pdf

(10) For this lapping, we used Monami’s Valve Grinding Compound #240. It is sold in a 200g can.

Enjoy Shooting !