News Category

Archive

Newly Posted

March Scopes’ bodies are manufactured by machining from solid aluminum bar stock discarding nearly 90% of it

Posted 09/09/2022

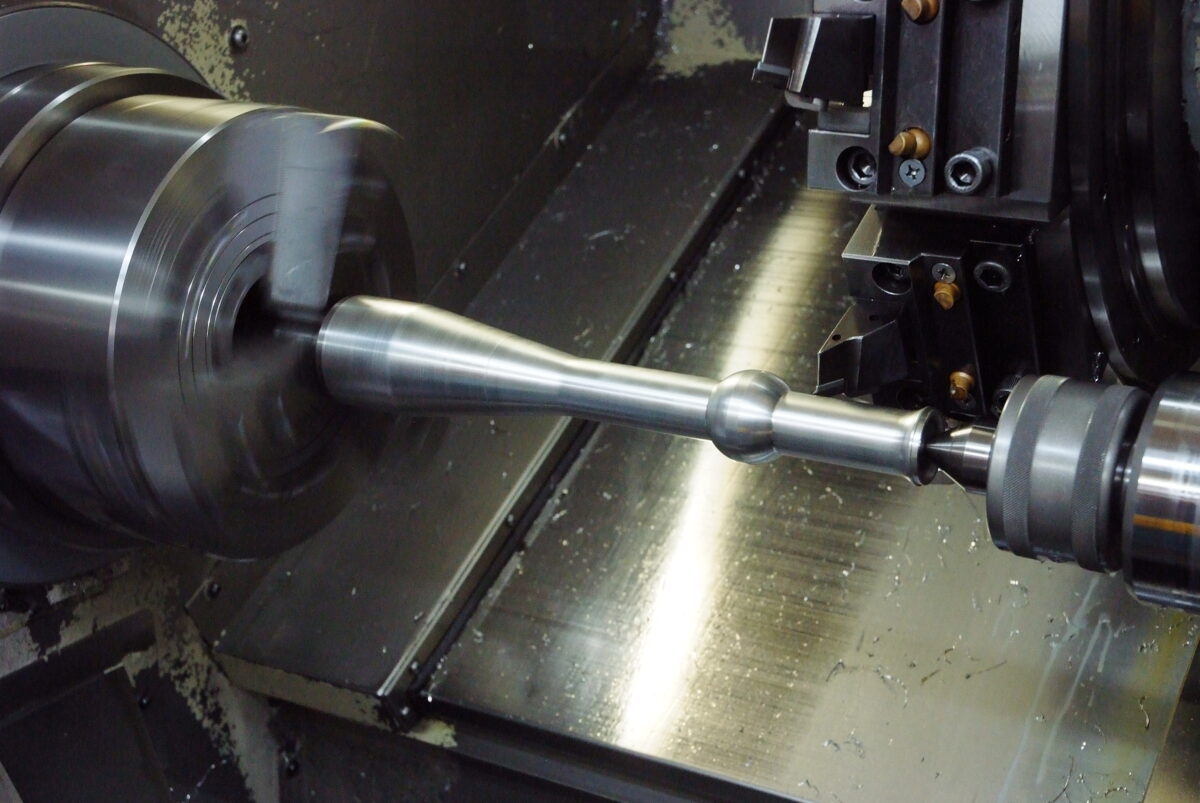

DEON Optical Design Corporation (manufacture of March Scopes) is a minor manufacturer manufacturing scope bodies by machining from solid aluminum bar stock. This is an uncommon way to manufacture a scope body as the material cost is very high and also the manufacturing process itself is expensive as it requires a long machining time. Please guess the weight of the solid aluminum bar stock. For 10-60×56 High Master scope, it weighs about 2.5kg (5.512lb). The aluminum bar is 20mm (0.79inch) thick. After we machine from the solid aluminum bar stock, the scope body will be 269g (9.49oz). We actually discard about 89.24% of the material. The size of the solid aluminum bar stock differs according to the scope model, but the material disposal rate is about the same for all, nearly or over 90%!

(The aluminum bar and the scope body in the pictures are for display at our factory. )

General method is the mainstream press molding which large companies mass producing riflescopes adopt because it is a much quicker, easier and most of all, cheaper manufacturing process. A press molded scope body costs only about 20% of what a machined aluminum scope body costs. The reason why press molding scope bodies is so cheap is because of the much reduced need for machining and that keeps the material and labor costs low. For example, the objective bell in a press mold scope body is widened by introducing a pipe into the body using a press. An even cheaper method of production is one where the objective bell is created separately from the body and the two parts are joined together during the manufacturing. The scope body blank undergo a cold forging operation using a large press. This operation will cause work hardening of the aluminum and the material will be stiff. The density of the aluminum will partially change and there will be internal stress, which will require annealing. The press molding a scope body requires much less final machining and so the cutting time is much shorter.

We know this because our founders have worked for decades for an optical company that manufactures OEM high grade riflescopes for many companies. It is undeniable that press molding manufacturing is much more efficient and cheaper than machining from bar stock. Press molding is a great manufacturing process that costs a lot less and saves money for the company.

We are a small custom manufacturer hand building each scope where there is a limit to the amount of production. When we considered the manufacturing method of a scope body, we made a decision in line with our company guideline “To do our best to support each and every shooter”. So though the machined scope body costs more than 5 times than that of the press molded scope it was a simple decision for us because we only want to do right for our discerning March Scope Owners. There are specific technical reasons why we chose the machining method explained in the following.

This process actually discards nearly 90% of the material during the machining process. The machining process is performed in two stages. When machining the aluminum bar stock, it is critical to do this at the proper pace to prevent the introduction of stress during the process. This is why we take our time machining the aluminum, little by little so as not to create undue stress in the scope body. Before undergoing the second stage of machining, we anneal the semi-formed scope body to completely relieve any stress. This process allows us to shape the body of the scope with meticulous precision.

By machining the scope body from solid aluminum bar stock, we do not stress the material and we are able to manufacture a very stable body with uniform density throughout. We eliminate the smallest distortion or eccentricity in the body and thus ensure that the body is perfectly aligned and will stay aligned through repeated firing and abuse thus providing you the shooter, with a dependable precision instrument. If the body is misaligned by just 1/100mm, this translates to 1cm at 100meter. (For American shooters: A .0005 misalignment in the body becomes a half inch deviation at 110 yards.)

We want our scope bodies to be strong and sturdy so that shooters can have complete confidence in their March scopes. We support shooters by providing the very best scopes on which you can rely on at all times. Thank you for your continued support!

Written by : Mari Morita