News Category

Archive

Newly Posted

3 reasons why March Scopes are strong and can be relied on at toughest conditions.

Posted 08/31/2021

We often receive inquiries if March scopes are capable of taking the recoil of large magnum calibers such as .50 caliber. We conduct an impact test up to 1000G (1000times of gravity) and we have also extensively tested on .50 BMG rifles. So the answer is YES. All our scopes can stand the impact of a .50 caliber recoil (including the .50 BMG) on usual shooting conditions. However, we understand that just being able to handle recoil may not be enough and that the body of the scopes should also be very strong and able to handle tactical environments. Let us explain 3 reasons why March Scopes are strong and can be relied on at toughest conditions.

1. No internal part is made of plastic excepting the few parts for the function they serve.

More than 150 parts used for March scopes are produced and supplied by Japanese manufacturers with the world’s highest technology to achieve the highest optical performance and durability. No internal part is made of plastic excepting the few parts that cannot be made of metal or glass because of the function they serve; for example, an insulator for the lighted reticle mechanism. We frequently talk to outside suppliers and our CEO Shimizu-san visits them from time to time to make sure that they meet up to March standards. We look for the very best all-Japanese parts and verify that they are always up to March standards.

2. March 34mm scope bodies have a 4mm thick wall.

The internal diameter of the 30mm tube and 34mm tube are the same at March Scopes. They are both 26mm. All March scopes with 34 mm scope body have a body thickness that is 4 mm, which is double that of the 30 mm body scopes. This does not mean that you cannot use 30 mm body scopes on your Magnum cartridges. All March Scopes including the 30mm scope body have passed the impact test up to 1000G (1000times of gravity). However as we prioritize the durability of the scope, our 34mm body tube is simply just to make the scope extra strong so you can have extra confidence.

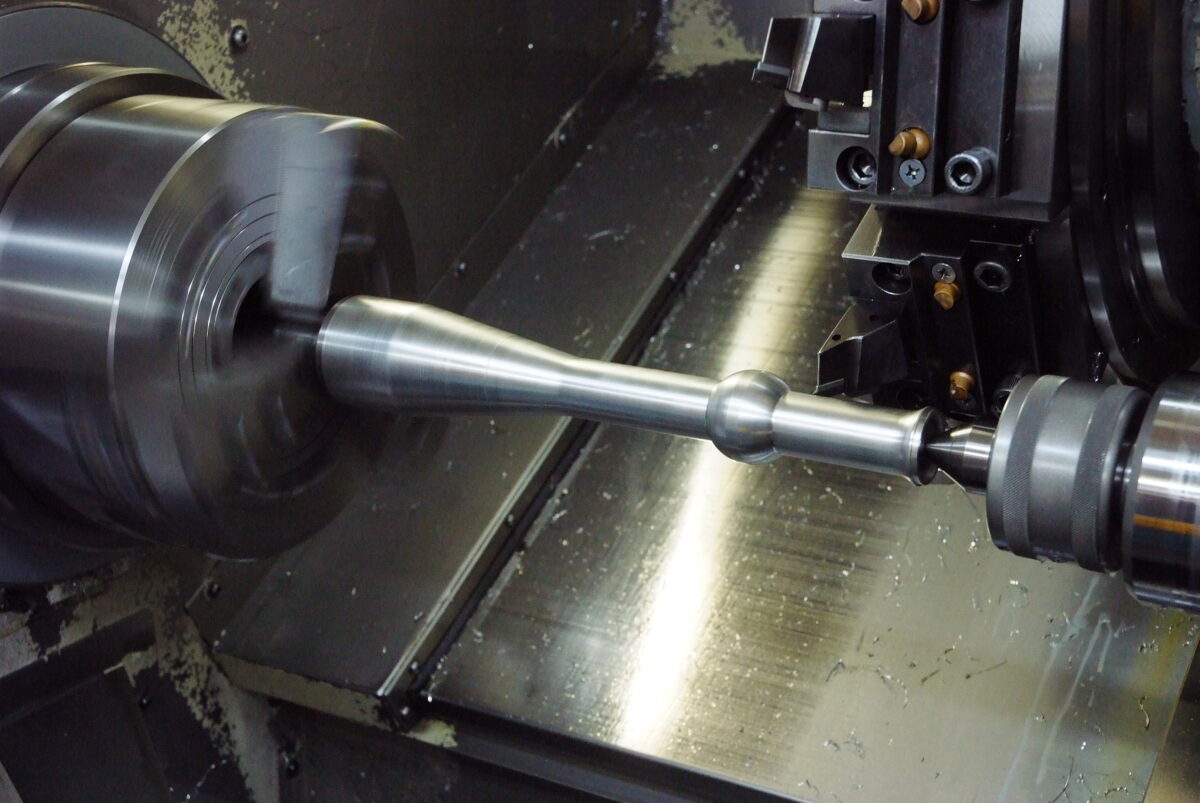

3. Our scope bodies are manufactured by machining from solid aluminum bar stock.

There are essentially two ways to make precision aluminum parts: Machining and Press Molding. At DEON (the manufacturer of March Scopes) we firmly believe in choosing the highest quality materials and parts and the best manufacturing processes. Our scope bodies are manufactured by machining from solid aluminum bar stock. This process actually discards up to 80% of the material during the machining process. By machining the scope body from solid aluminum bar stock, we do not stress the material and we are able to manufacture a very stable body with uniform density throughout. We eliminate the smallest distortion or eccentricity in the body and thus ensure that the body is perfectly aligned and will stay aligned through repeated firing and abuse thus providing you the shooter with a dependable precision instrument.

If you are interested in learning more about the machining process, you can check from our previous article.

March Scope’s relentless effort for Utmost Quality – Machined Aluminum Scope Body

We support shooters by providing the very best scopes on which you can rely on at all times.

Written by : Mari Morita